BATTERY TECHNOLOGIES

CONCEPT MANUFACTURING DESIGN

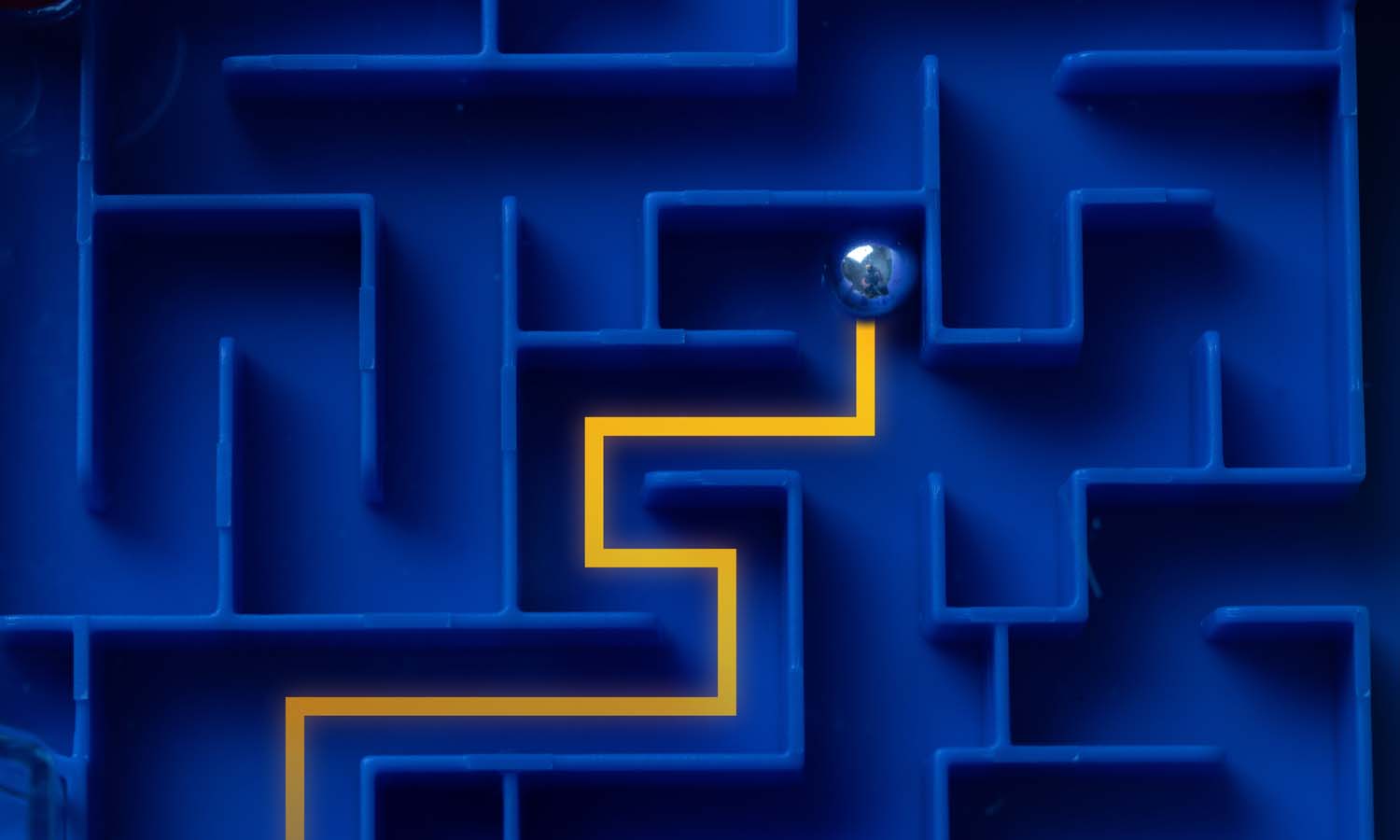

Our Approach

We develop high-level layouts, automation strategies, and facility concepts, including make-vs-buy analyses. By focusing on optimisation early, we design flexible and efficient systems that reduce risk during later phases. This proactive approach ensures that manufacturing designs support smooth transitions from concept to production, helping businesses avoid costly changes and accelerate progress toward operational readiness.

BENEFIT 1

Embedding Design for Manufacture and Assembly Early

The first benefit is enabling design for manufacture and assembly principles to be embedded early. By collaborating closely with design teams, we ensure products are engineered with manufacturability in mind. This reduces complexity, improves quality, and shortens development cycles, ultimately lowering costs and accelerating the transition from design concept to production readiness. A validated concept will enable convidence in project budgets, required footprints, labour and costs.

BENEFIT 2

Developing Clear and Competitive RFQs

The second benefit is supporting the development of RFQs (Request for Quotation) based on the concept designs. By translating high-level layouts and process requirements into clear, detailed RFQs, we enable businesses to approach suppliers with accurate specifications. This reduces ambiguity, ensures competitive and relevant bids, and accelerates procurement, ultimately helping organisations secure the right equipment and partners at the best value.