BATTERY TECHNOLOGIES

DIGITAL & VIRTUAL VALIDATION

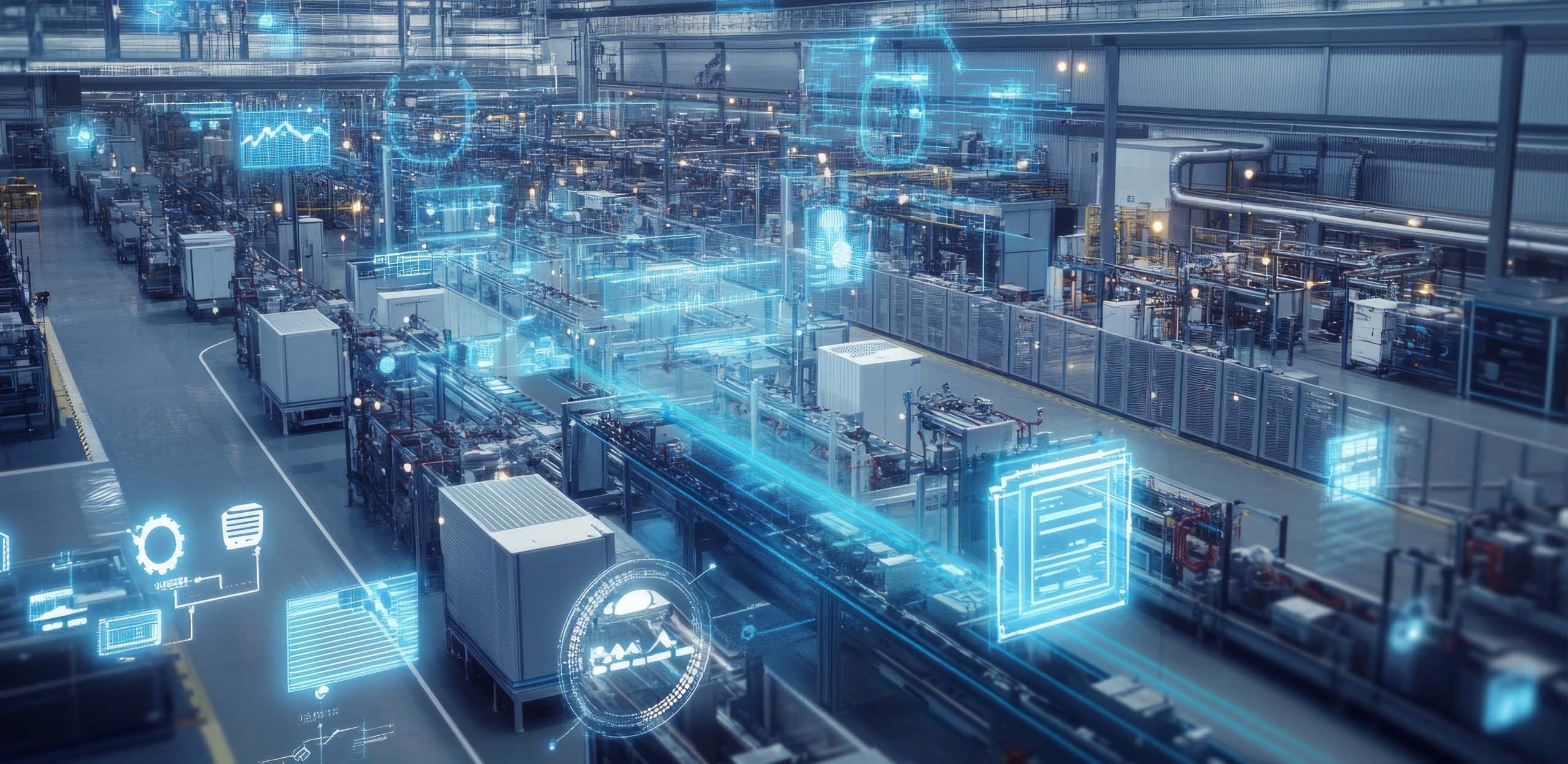

Our Approach

We apply digital twins, process simulations, and virtual commissioning to test manufacturing systems before physical implementation. This data-driven, digital-first approach allows inefficiencies and bottlenecks to be identified early, significantly reducing the risks associated with commissioning. It provides clear evidence of performance, enabling smarter design choices and reducing uncertainty before large-scale capital investments are made.

BENEFIT 1

Lowering Commissioning Risks and Costs

The first benefit is lowering commissioning risks and costs. By validating designs in the digital space, businesses reduce rework, avoid downtime, and minimise unforeseen installation challenges. This saves significant capital and operating costs while also providing reassurance to stakeholders. Early identification of bottlenecks ensures smoother start-up and reduces the likelihood of disruptions once production is launched.

BENEFIT 2

Accelerating Time-to-Production

The second benefit is shortening time-to-production. Validated digital designs allow businesses to progress quickly from planning to full operation, avoiding delays associated with troubleshooting physical systems. This acceleration means companies can capture market opportunities faster, generate earlier revenue, and adapt production capacity more responsively to customer demand in dynamic battery markets.