DIGITAL MANUFACTURING

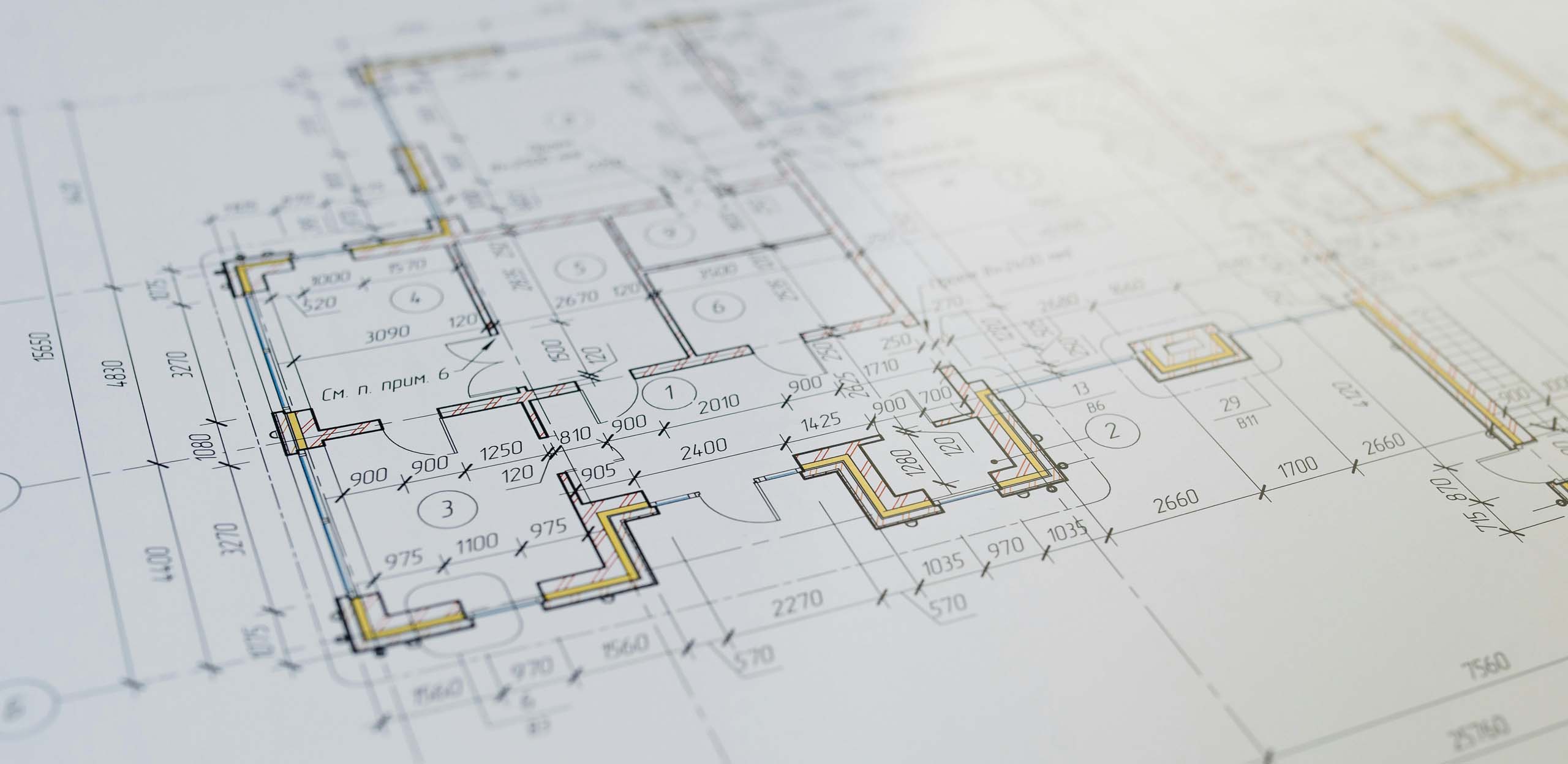

LAYOUT PLANNING

Our Approach

We use advanced digital tools to design, visualise, and optimise factory layouts. Our methodology integrates material flow, equipment positioning, and space utilisation optimising the physical infrastructure of a manufacturing facility to maximise volume throughput within spatial constraints. Leveraging lean manufacturing principles and workflow optimisation to create an environment that maximises efficiency while supporting safety and scalability. This process can work for validating both greenfield and brownfield facilities to ensure alignment with scalability and key performance indicator forecasts.

BENEFIT 1

Optimised Layouts for Productivity

Optimised layouts reduce wasted space and unnecessary movement, leading to smoother production flows and improved productivity.

BENEFIT 2

Virtual Validation of Facility Investments

Virtual layouts allow clients to validate investments before implementation, reducing costly errors and ensuring facilities are future-proofed.